India’s Leading Injection Molding Machine Manufacturer

Your Reliable Partner and Trusted Injection Molding Machine Manufacturer

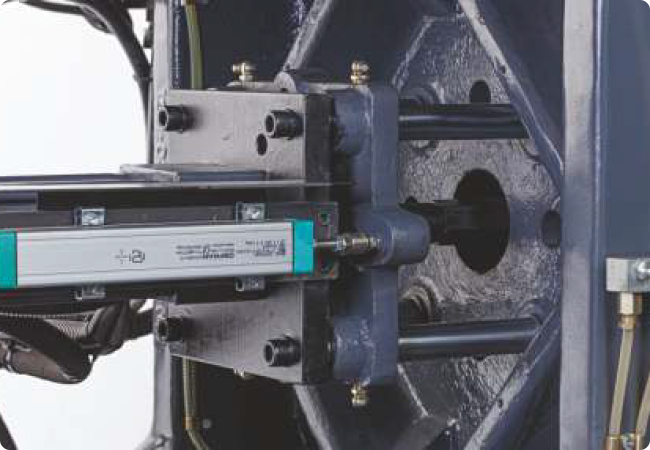

Servo Injection Molding Machines in Ahmedabad

High-Precision & Efficient Solutions

Check Some Of Our Counter

20% to 30%

Durable Performance in High

Pressure Easy to Maintenance

30% to 50%

Hydraulic System Precise and Faster

Response Reduced Heat Generation.

Energy Efficient Saves

20% to 30%

Improved System Response

Durable Performance in High

Pressure Easy to Maintenance

Energy Efficient Saves

30% to 50%

Faster Response Towards

Hydraulic System Precise and Faster

Response Reduced Heat Generation.

Serving Various Industry Segments

Our machines are crafted with precision and efficiency in mind, ensuring optimal performance and reliability. From small-scale production to large-scale manufacturing, Parth Plastech stands among the Best plastic injection moulding machine manufacturers in India. We also specialize as a trusted PVC Injection Moulding Machine Manufacturer and PET Injection Moulding Machine Manufacturer, serving diverse industry requirements with high-quality, durable, and efficient solutions.

Our Offices

Our Offices

Our Offices

Our Offices

Our Offices

Our Offices

Our Offices

See What Clients Are Saying

We are very proud of the service we provide and stand by every product we carry.

Read our testimonials from our happy customers.

Innovation Showcase

Explore our Innovation Showcase to witness the cutting-edge projects and engineering marvels that define our commitment to excellence. From groundbreaking technologies to innovative solutions, this gallery offers a visual journey into the heart of our engineering expertise. Immerse yourself in the future of engineering as we showcase the passion, precision, and progress that drive our projects forward.